Dust Control Triggers

The PHAI dust management plan recognizes that uncontrolled dust from project activities can be both a nuisance and a potential hazard to people and the environment. For this reason, preventing and controlling dust is the responsibility of all work-site personnel, who are trained to take prompt action whenever visible dust is observed.

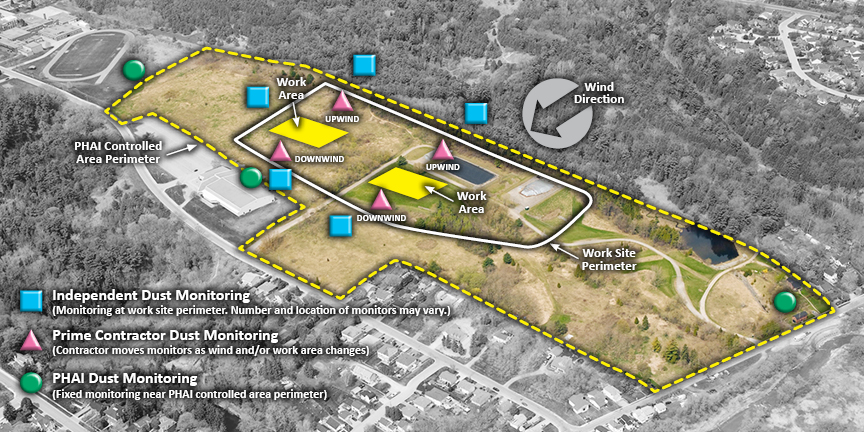

Continuous, real-time monitoring is used to measure the total dust being generated when work is underway, and the results are checked against pre-established levels – administrative control levels and action levels. Both levels are well below Ministry of the Environment regulatory limits but, nonetheless, act as triggers that require work to be stopped and immediate action to be taken if reached.

The PHAI dust management plan has been developed around the fundamentals that for dust to become airborne, exposed soil, dry conditions and wind must be present. By avoiding or managing these, dust can be prevented and controlled.

Prevention

Before starting work, dust prevention measures include:

- Dampening soil in dry areas

- Reducing activities or loads to avoid unnecessary dust generation

- Using wind fencing around work areas

- Postponing work activities likely to cause dust if sustained wind speed is predicted to exceed 36 km/hr., unless the contractor can demonstrate that the work site is sufficiently protected so wind will not generate dust

Control

During work, dust management measures include:

- Taking prompt, corrective action, such as dampening soil, when dust is observed

- Minimizing areas of exposed soil and applying nightly cover

- Tarping, monitoring and cleaning trucks transporting soil or waste

- Stopping dust generating activities if sustained wind speed exceeds 36 km/hr for two hours, unless the contractor can demonstrate that the work site is sufficiently protected so that wind will not generate dust

Monitoring